Sintrol Dust Monitors

Dust Monitoring Solutions

Sintrol dust monitors reduce discovery time for filter malfunctions, thereby, reducing maintenance costs, preventing equipment contamination and product loss, and ultimately increasing plant availability.

Read moreSintrol designs and manufactures particulate matter measurement devices for the domestic and export market. In addition, Sintrol is focusing on process industry analysis, process protection, measurement, automation, NDT and laboratory equipment. One of our strengths is our willingness and ability to deliver not only individual devices but also comprehensive solutions that support our customers’ business.

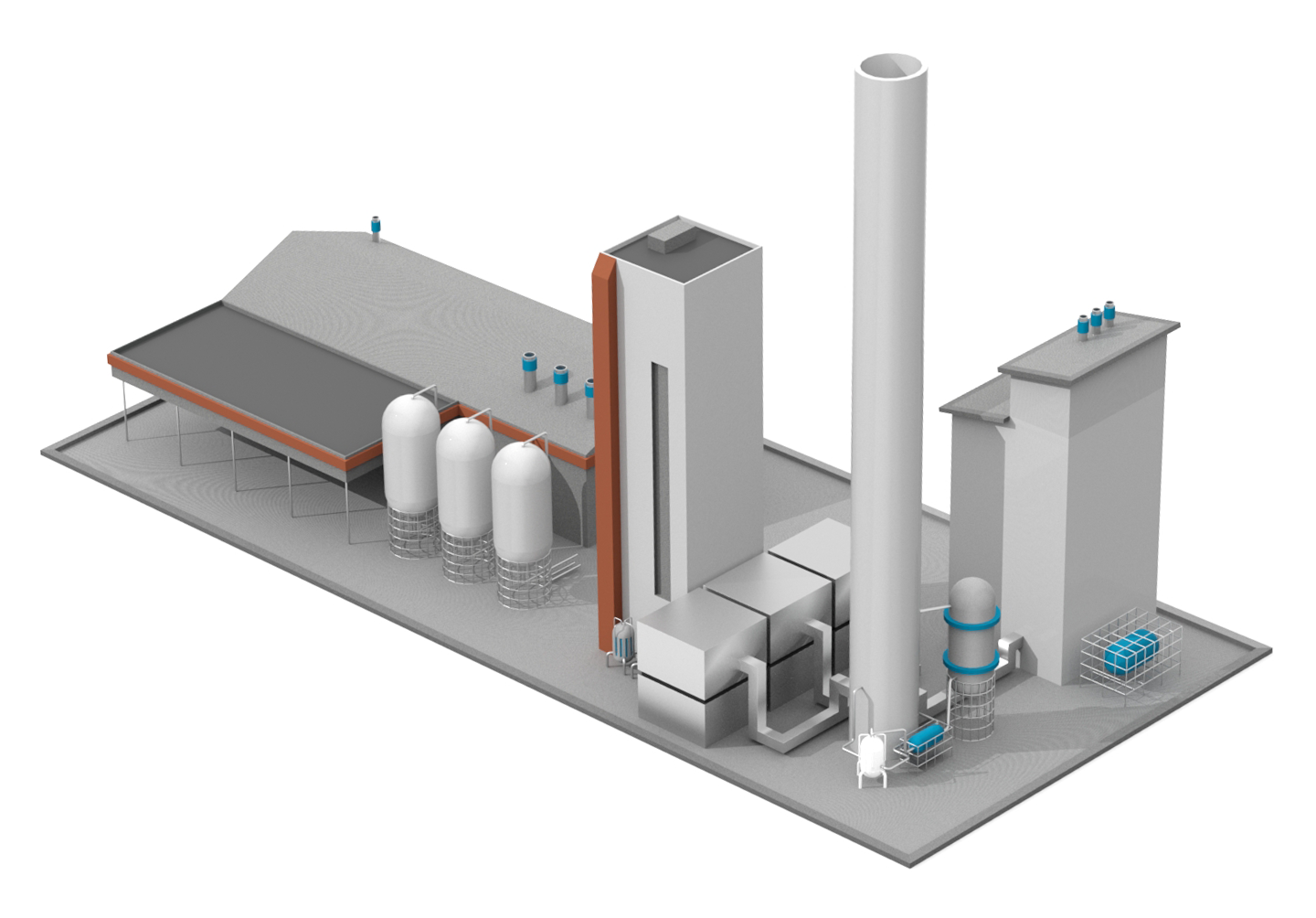

Sintrol delivers comprehensive instrumentation solutions for both recovery and power boilers. With our strong expertise and experience of challenging process environments projects, we can guarantee the best suitable solution for you.